Rail

EverPel is ideal for application to railroad infrastructure, tank cars, and more. Replacing high-VOC epoxy coatings and linings, EverPel can create an ultra-slick, oil-repellent surface on the interior of tank cars, allowing for easy upload, prevention from depositions/fouling, and simplified maintenance/cleaning operations.

Storage

EverPel for storage tanks protects the surface substrate in highly corrosive environments. The non-toxic and water-based formulation is far less hazardous to apply than typical epoxies, yet protects against adhesion and deposition of elements within chemical or oil/gas-containing tanks.

Infrastructure

EverPel combats atmospheric and galvanic corrosion on both internal and external components of critical infrastructure, like bridges and roadways. EverPel vastly outperforms traditional coatings in preventing corrosion on aluminum and steel substrates, helping to arrest existing corrosion or to protect new infrastructure.

EverPel's long-lasting protection can reduce maintenance costs and extend equipment lifetime.

EverPel variants are specially formulated to impart extreme corrosion and chemical resistance to a wide range of substrates, without the need for extreme and costly surface preparation. EverPel forms a repellent, slick barrier against corrosion and the deposition of other debris like scales, hydrates, and iron sulfides.

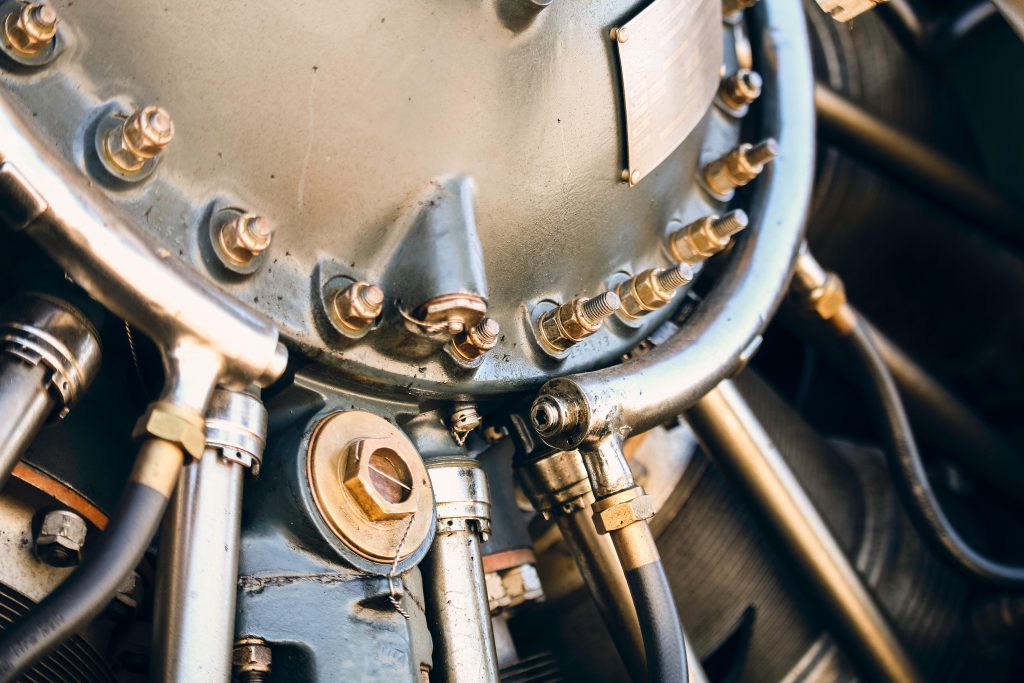

Wide variety of applications

EverPel has a wide variety of applications across sectors such as energy, logistics & transportation, storage, energy, aerospace, and more.

Tribological properties

EverPel imparts extremely low surface energy, reducing friction and enabling easy product release + active repulsion of aqueous and gaseous corrosive species such as H2S and CO2.

Extensive testing

EverPel has been tested extensively for non-reactivity with a wide variety of heavily corrosive species and is functional on surfaces/equipment exposed to water/hydrocarbon products.